Is RFID systems really need of time?

An typical supply chain is an end-to-end process with the principle reason for creation, transportation, and conveyance of items. It is comparative with the items' developments from the provider to the maker, wholesaler, retailer lastly to the end customer. Also, an inventory network is a mind boggling combination of gatherings that require coordination, cooperation, and data trade among them to expand usefulness and productivity A supply chain is comprised of People, exercises, and assets engaged with moving items from providers to clients and data from clients to providers. Hence, the recognizability of coordinations streams (physical and data) is a vital issue for the definition and plan of assembling measures, improvement of design and increment of safety in work regions.

Traditional system of tracking:

Traditionally, the traceability system is performed through the asynchronous fulfillment of checkpoints (i.e. doorways) by materials. In such cases, the tracking is manual, executed by operators. Often companies are not aware of the inefficiencies due to these systems of traceability such as low precision and accuracy in measurements (i.e. no information between doorways), more time spent by operators and costs (due to the full-effort of operators who have to trace target positions and movements). According to every day millions of transport units (cases, boxes, pallets, and containers) are managed worldwide with limited or even with lack of knowledge regarding their status in real-time. In order to overcome the lack of data due to traceability, automatic identification procedures (Auto-ID) could be a solution. They have become very popular in many service industries, purchasing and distribution logistics, manufacturing companies and material flow systems.

Programmed recognizable proof systems give data about individuals, vehicles, merchandise, and items on the way inside the organization. It is feasible to take note of a few benefits utilizing a automatic identification system like the decrease of robbery, increment of safety during the vehicle and distribution of assets, an expansion of information on articles' situation continuously.

Radio Frequency Identification (RFID)

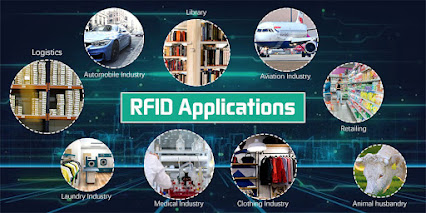

According to RFID tags Manufacturer in USA, Now a days the application of RFID has draw attention of scientists as well as managers faced with the problem of optimizing production processes in several industries . RFID has enormous economic potential, which many manufacturers (e.g. Ebay, Tesla, Burger king) and retailers have already recognized its benefit and started to use successfully .

The main utilization of RFID frameworks in mechanical applications manages with asynchronous identification. old barcode label framework that set off an insurgency in ID frameworks are lacking in an expanding number of cases. Barcodes might be incredibly low cost, however their constraints are their low storage capacity and the reality they can't be reprogrammed. A barcode is an optical machine-meaningful portrayal of information, which shows information about the item to which it is attached. In contrast to a RFID, a standardized tag addresses information by changing the widths and spaces of equal lines, and may refer to a linear or one-dimension (1D).

Radio frequency ID (RFID ) is a technique for collecting and retrieving information through electromagnetic transmission to a RF viable coordinated circuit. RFID situating frameworks are regularly utilized in complex indoor conditions.

RFID function is to identify an object through radio frequency transmission. The main purpose of RFID technology is to assume information about live Stock , Goods, or people identified by small tools in radio frequency associated to them. According to the Best RFID tag Manufacturer in USA some of the more transparent advantages of RFID are as follows:

Some of the benefits of RFID:

• Tracking assets and managing inventory

• Saving time and money through automation

• Improving information exactness and accessibility

• Enhancing wellbeing and security

• Enhanced quality and traceability

• Better control of production

• Increased incomes

• More in-depth management information

RFID systems offer benefits for businesses of all sizes, allowing them to rapidly improve efficiency and reduce cost by automating processes and improving utilization of assets and quality. RFID can form the basis of an effective asset management system and is also at the heart of the Internet of Things.

Comments

Post a Comment